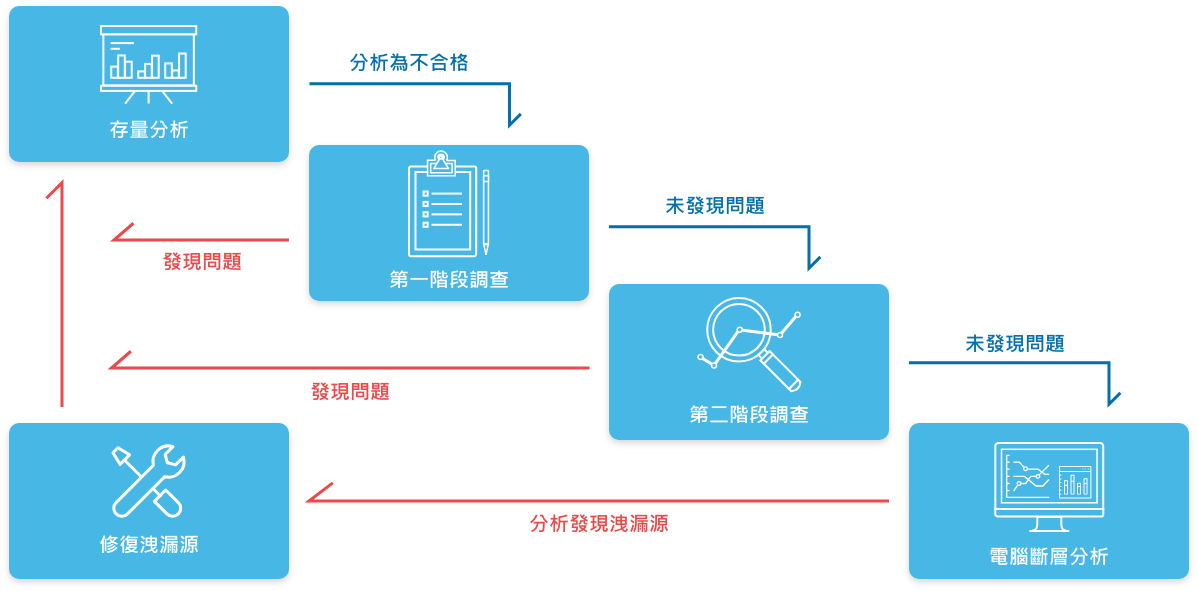

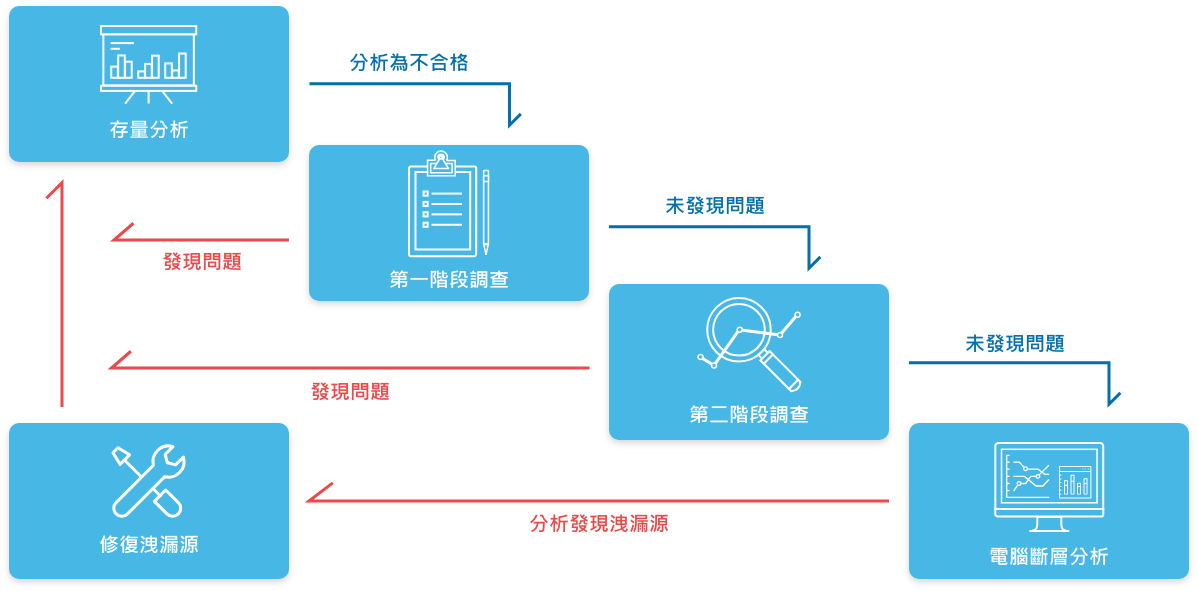

監測流程

定期監測

每月定期監測。每月8日提供總量管制表交由臺灣脈思監測團隊整理後送至國外技術單位分析。

洩漏損失調查

監測發現油料損失。經由專業的現場洩漏損失調查,幫您找出並排除問題。

電腦斷層

以電腦斷層技術探測輸油管、卸油管與油槽,確實找出油槽系統漏源。

使用最先進的監測模式進行存量分析,以每小時190c.c.的洩漏損失率判斷地下儲槽及管線系統是否處於洩漏或損失狀態。

總量管制表常因油槽係值表不正確而難以掌握真實盈虧,導致無法第一時間發現洩漏。

從多次的監測經驗實務中,我們發現多數加油站皆有流量計超發問題,此一發現,幫助業者減少隱性營業損失。

卸油量誤差為我們監測分析中的重要一環,能間接保障業主權益。

業主經由我們提供不明損失的油料公升數及日期等資料,找到油料損失的關鍵原因。